-

Floor Stencils - Garbage Can

$174.89

$135.19

Supplied in: Each -

Floor Stencils - Fire Extinguisher

$174.89

$135.19

Supplied in: Each -

Floor Signs - Utility Cart

From $37.09 To $100.99

From $15.59 To $72.79

Supplied in: Each -

Floor Signs - Pallet Jack Parking

From $37.09 To $100.99

From $15.59 To $72.79

Supplied in: Each -

Floor Signs - Red Tag Hold Area

From $37.09 To $100.99

From $15.59 To $72.79

Supplied in: Each -

Calibrated By Date Due Labels For Greasy Surfaces

$145.59

$135.19

Supplied in: Label -

Labels For Greasy Surfaces - Inspected Date Initials

$145.59

$135.19

Supplied in: Label -

Floor Signs - Forklift Parking

From $37.09 To $100.99

From $15.59 To $72.79

Supplied in: Each -

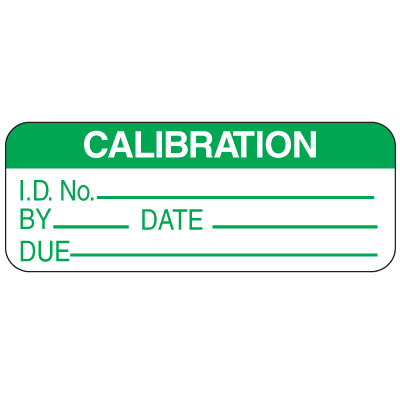

Calibration ID No. By Date Due Labels For Greasy Surfaces

From $145.59 To $201.09

From $135.19 To $187.19

Supplied in: Label -

Tested For Electrical Safety By Date Labels For Greasy Surfaces

$145.59

$135.19

Supplied in: Label -

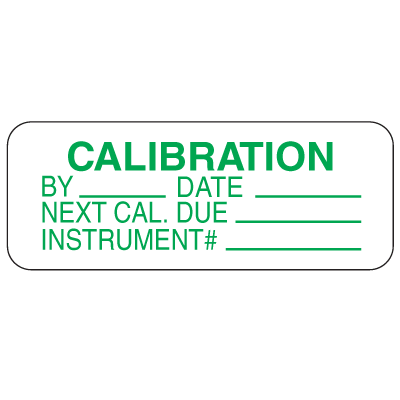

Calibration By Date Instrument # Labels For Greasy Surfaces

$145.59

$135.19

Supplied in: Label -

Warning Anti-Skid Tape - Black/Yellow Striped

$183.02Supplied in: Feet -

Calibration Not Required Labels For Greasy Surfaces

$145.59

$135.19

Supplied in: Label -

Shadow Board Tool Tape

$79.99Supplied in: Feet -

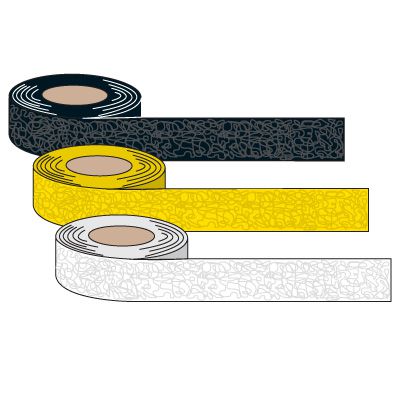

Waterproof Anti-Slip Tape

From $67.49 To $387.59

From $57.19 To $207.99

Supplied in: Feet -

Magnetic Vinyl Holders

$92.89

$51.99

Supplied in: Each -

Brady® ToughStripe™ Floor Marking Tape

From $115.99 To $150.99Supplied in: Roll -

Tested Date Initials Labels For Greasy Surfaces

$145.59

$135.19

Supplied in: Label -

High Visibility Overhead Signs - Pallet Storage Area

From $107.29 To $182.89

From $64.39 To $109.79

Supplied in: Each -

Maintenance By Date Write On Labels

$143.00Supplied in: Pack of 25 Each -

Floor Signs - Mop Bucket

From $37.09 To $100.99

From $15.59 To $72.79

Supplied in: Each -

Economy Status Boards - Stock Magnets

$22.59

$10.39

Supplied in: Each -

Production Control Tags - Defective Do Not Use

$2.09

$0.89

Supplied in: Each -

All Months Of the Year Stickers

From $31.19 To $152.79

From $20.79 To $47.89

Supplied in: Label

5S

The goal of 5S (Sort, Set in Order, Shine, Standardize, Sustain) is to create a clean, orderly environment leading to a pattern of logical work. 5S, in conjunction with greater lean manufacturing principles, enhances productivity by eliminating waste. To accomplish this, a business must:

Discard unused items

Organize what’s left

Clean work surfaces

Set a standard for organization

Maintain improvements in the future

Get started on 5S training today with Seton. We offer everything you need to begin or improve your existing 5S program and get you closer to your lean goals. Click here to view the Lean 5S Product Selection Guide

.

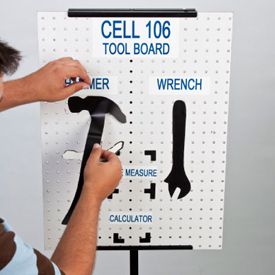

What is 5S?

The 5S program is part of lean manufacturing, which seeks to eliminate waste and enhance productivity. There are five steps to a successful 5S system:

Sort -Discard unused items. The idea is to keep items used regularly close by.

Shine - clean work equipment and areas. Cleaning serves to eliminate sources of contamination and helps to identify abnormalities before they lead to defects.

Set in order- Organize the remaining items at your workstation. Clearly label everything and assign each item a spot.

Standardize- Develop scheduled and checklists to ensure procedures are followed. This step helps ensure cleanup and organizational procedures continue on a regular basis.

Sustain - Management helps to ensure all 5S items are being followed and workers are on schedule.

Get started on 5S training today using a variety of items from Seton. Our 5S products help you either get started on your own 5S program, or enhance your current system.